PROMIS And Safe Maintenance

The resource of PROMIS® to meet customer demands in terms of quality, good design and effectiveness in a competitive way, which exploits the knowledge of experts and makes it easily and economically available to users. The resource includes Occupational is aimed at allowing a company to set up its structure Safet and Process Safety methods for production operations.

The area of Health Safety and Environment has model structures of management systems and guidance on meeting legal and industry best practice requirements.

Maintenance appears as an activity, which in itself may be hazardous, and as an activity that prevents hazards. Such activities are:

• Permit to work

• Confined space entry

• Hot work

• Working at heights

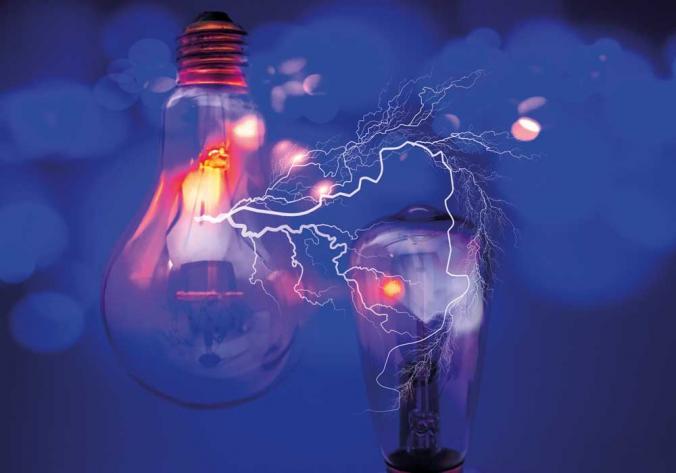

• High voltage work

• Working on pressurised systems

• Working with unstable and reactive chemicals

• Management of Change

• Safe Work procedures and Job Safety Analysis

• Mechanical Integrity

All the above listed actions address hazards without being buried in bureaucracy that might lead to:

• ‘Tick the box’ mentality where hazardous working conditions are unnoticed because most of the pre work activity is centred on filling out forms in an office or control room

• Loss of efficiency

• Loss of focus on the real hazards

In normal conditions maintenance reduces risk as:

• Mechanical integrity inspections and testing of process containment systems such as pipes, pressure vessels, storage tanks and heat exchangers

• Relief systems inspection and testing

• Safety critical equipment testing such as safety trips and interlocks, safety instrumented systems (as regulated by the standard IEC 61511), fire protection, emergency equipment

• Managing the risks of flammable and explosive atmospheres (covered by the ATEX directive)

• Maintenance of lifting equipment

The faults are discovered by testing and remedial work carried out to make sure that the systems are maintained in an optimal state, available and fit for purpose, thus reducing occupational and major hazard risks.

Over the last 3 years, experts in the fields of Quality, I.T., Health, Safety and Environment produced the resources within PROMIS, making them easily and economically available to Small and Medium Enterprises (SMEs) and any consultants who support them. ‘Maintenance Aligned’ issues are developed within PROMIS.

PROMIS is designed for Small and Medium Enterprises. A lot of effort has been made to understand how SMEs function. Large companies have departments devoted to maintaining good performance and legal compliance. Many small companies do not have the resources to do this but must comply with the same laws and industry norms as large companies.

In an SME a person may have several roles. This person fulfils the responsibilities through his or her own work and in some cases the use of external resources. In the latter case, the cost might be significant and some ‘learning by doing’ is lost. This is common for the Safety Report required for ‘top tier’ establishments covered by the Seveso III Directive, which will replace Seveso II Directive on 1 June 2015. It is beneficial to give the SME tools that can be adapted for their own use. A positive aspect of this is in the management of Process Safety Risk Management:

• Identifying hazards

• Estimating severity of the consequences of these hazards

• Estimating likely frequency of the hazards occurring

• Managing and reducing the risks to achieve a level meeting legal and company criteria

If large parts of these are carried out by external specialists, opportunities for operating within a ‘safe envelope’ are missed. An example illustrates the point.

In chemical production process that handles unstable, toxic or flammable materials, Risk Management is best carried out with a multifunction team including the plant operations personnel. This ensures that staff operating at the plant understand:

• The hazards of the materials handled (toxicity, flammability etc.)

• The risks

• The potential consequences to workers, the community and the environment if control is lost

• Their role in managing the facility safely (since the most influential role is often that of the plant operative)

• What to do if significant deviations occur (e.g. response to alarms and emergency action)

• Alert management when systems are degraded

The content and training within PROMIS places simple tools in the hands of the subscribers. These are designed to be user friendly for operations staff. Backing up these two sides of the ‘pyramid’ is a services provision, which will allow the subscriber to consult the specialist(s) who have created the content and training materials. This assistance is on an exception basis and would be negotiable between the subscriber and specialist.

Access to a free of charge overview and demo of PROMIS maintenance and PROMIS Chemical Process Safety in 7 languages is available at the following link: www.promislingua.eu