RCM or Not? Are You Shooting Mosquitos With a Big Canon?

Reliability Centered Maintenance (RCM) promises improved reliability, but is it always worth it? Full-scale implementation is often overly complex, costly, and unnecessary—like using a cannon to shoot a mosquito. Without readiness and a strong foundation in basic maintenance practices, RCM can distract from more practical, cost-effective solutions. Simpler, experience-driven approaches may often yield better results.

The first time I learned about elements of Reliability Centered Maintenance (RCM) was in 1968 when I spoke at a conference in Stockholm with Professor Horst Grothus. Since then, I have used one part of his teaching – the theory of failures in manufacturing equipment. Failures can occur randomly or regularly in time. Some failures have a time lapse from the point of failure to breakdown (functional failure). Understanding this theory helps you understand the different types of failures and the difference between a failure vs. a breakdown. The chart below can be used as a model to describe failure distribution in time. I call the time between failure and break down the Failure Developing Period (FDP).

Everything else such as criticality, failure mode and effect analyses, hidden failures, etc. we have already used. In the 1990s there was a lot of training and interest in RCM, but it fizzled out relatively soon because industry quickly realized that it was way too complicated — and practically impossible — to justify a full-blown implementation. Some equaled RCM with "shooting mosquitos with a big canon."

RCM should be understood and used in early design of equipment and manufacturing processes.

One plant I worked with did decide to take on a complete RCM implementation, then after spending two million dollars they gave up because no results were delivered. Reasons for this included:

• It was way too complicated and time consuming.

• The very core of maintenance work management including prioritization, planning and scheduling of work orders is not included in RCM, and this diverted improvement initiatives of these processes

RCM can be useful to do for very complicated and advanced pieces of equipment and manufacturing processes. I have worked in hundreds of manufacturing plants and engine rooms on ships, and I estimate that RCM can be justified for about a whopping 3% of all equipment.

When would you be ready to implement RCM?

If you decide to implement RCM in your plant, be sure that your organization is ready for it. If you are not ready for it, you will divert your attention from more important and cost-effective improvement initiatives you can do. If you are not prepared, an RCM implementation would be a waste of time and money.

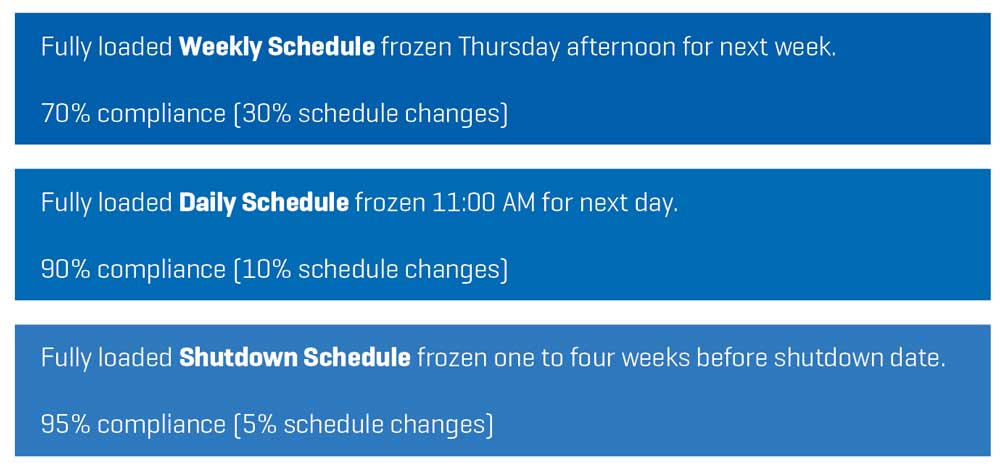

An example of when your organization is ready for more advanced initiatives (including RCM on very select equipment) is when the very basics of reliability and maintenance processes are instituted and sustainable. The chart below can serve as an example of readiness in your organization.

The results presented by RCM advocates are not relevant in most plants. They claim reduction of Preventive Maintenance tasks by 65 – 75%. These results are from military equipment including the navy, where fixed time replacements and overhauls was used for all equipment. Of course, you can eliminate 65-75% of all PM tasks in that situation, but you do not need RCM to do that; you can use knowledge of failure theory, common sense, and experience instead, and move fixed time tasks to condition monitoring.

RCM should be understood and used in early design of equipment and manufacturing processes. At this stage, criticality of the manufacturing process using Reliability Block Diagrams combined with RCM and maintainability design would deliver more reliable and maintainable equipment.

Undertaking an RCM training and implementation of what you learned is an unnecessarily expensive and time-consuming initiative. It will divert your focus on the basics and more cost-effective improvement efforts, so before considering using RCM, do not expect to get the exaggerated savings that are proposed by some enthusiasts for RCM unless all your Preventive Maintenance consists of fixed time replacements and repairs.

IDCON provides short one to two days of training which is useful to understand different types of failures, how they develop and how they might occur in time. If you have very critical systems or equipment that are new to you, a focused RCM exercise can be helpful but remember that using your team's experience and common sense most often leads to the same or better results.

TeXT: Christer Idhammar, Founder, IDCON INC

Photos: IDCON

![EMR_AMS-Asset-Monitor-banner_300x600_MW[62]OCT EMR_AMS-Asset-Monitor-banner_300x600_MW[62]OCT](/var/ezwebin_site/storage/images/media/images/emr_ams-asset-monitor-banner_300x600_mw-62-oct/79406-1-eng-GB/EMR_AMS-Asset-Monitor-banner_300x600_MW-62-OCT.png)