Selecting the Correct Bearing Seal

Seals keep lubricant in the bearing and bearing chamber, and exclude contaminants.

The primary functions of a bearing seal are to keep lubricant in the bearing and bearing chamber and to exclude contaminants. Some seals are integral to the bearing; others aren’t. The focus here is on what to consider when selecting external bearing seals.

Key factors for selecting the right bearing seal for an application typically include:

• Bearing type (rolling or sleeve)

• Lubricant (oil or grease)

• Seal friction and consequent heating

• Shaft surface speed and finish

• Physical space available

To select the appropriate seal for a given application, match the relevant factors from the above list with the characteristics of the following external seal types.

Common types of external seals

The types of seals most commonly used with rolling (ball and roller) bearings are contact or lip seals (Figure 1), non-contact seals (Figure 2), and to a much lesser degree various kinds of bearing isolators (Figures 3, 4 and 5) that combine the functions of contact and non-contact seals in different ways. The labyrinth seal (Figure 6) is a non-contacting seal that’s normally used with sleeve bearings.

Contact seals. Contact seals form an effective sealed interface by applying continuous pressure to the shaft surface with a resilient material. These seals make it difficult for fluids or solids particles to penetrate the sealed area, but direct contact with the shaft creates friction and heat that can degrade the seal and damage the shaft’s surface finish. If a less effective sealing method is acceptable, an alternative is a non-contact seal.

Non-contact seals. Non-contact seals produce much less friction (if any) and heating than contact seals. Unfortunately, they also allow lubricant to leak out of the bearing chamber and liquid or physically small contaminants to enter.

Bearing isolator seals. Bearing isolators combine the characteristics of contact and noncontact seals in a single unit but use the contact features to “drive” part of the seal at the shaft’s rotating speed. Such seals afford more protection than individual contact or non-contact seals.

They also can be used with either grease or oil lubrication, and with sleeve or rolling bearings.

Although bearing isolators are more costly and require more physical space than contact or noncontact seals, they deliver more effective sealing.

• Contacting isolators. The first bearing isolators were non-contact labyrinth seals that greatly reduced contamination ingress but didn’t stop moisture or other vapors. A newer version called a contacting isolator (Figure 4) uses rare-earth magnets to apply tension to lapped contacting faces, just like a mechanical pump seal. Although contacting isolators stop all solid and vapor contamination, they have surface speed limitations–a maximum of about a 4" (100 mm) shaft at 3600 rpm.

• Labyrinth-design isolators. Another variation of the bearing isolator has a labyrinth design and an O-ring or other elastomer element that keeps the labyrinth channel closed when the shaft is stopped and expands by centrifugal force to open the channel when the shaft is rotating. This prevents vapor ingress while the machine is off and eliminates friction/heat when it’s running. Special long-relief isolators are used in sleeve bearing applications to accommodate the bearing’s axial end float.

• Shaft slingers. These seals combine elements of contact and non-contact seals (Figure 5). Shaft slingers make contact with the end bracket while the machine is idle and move away from it (by centrifugal force) when the shaft is rotating.

Labyrinth seals. Another type of non-contact seal in common use is the labyrinth seal (Figure 6). Labyrinth seals can be used with rolling or sleeve bearings, and with oil or grease lubrication. Suggested clearances for labyrinth seals with oil-lubricated sleeve bearings are given in Table 1.

Suggested diametral clearances for labyrinth seals with grease-lubricated rolling bearings are 4-8 mils per inch (0.04-0.08 mm/cm) for shaft diameters below 2” (50 mm), and 5-10 mils per inch (0.05- 0.10 mm/ cm) for shafts 2” (50 mm) and larger.

Seal selection

Contact seals or bearing isolators are good choices for most oil-lubricated bearings, with the major exception of sleeve bearings for which labyrinth seals are commonly used. Non-contact seals aren’t acceptable in most oil-lubricated applications because they allow leakage.

The options for grease-lubricated bearings run the gamut, from non-contact and contact seals to various kinds of bearing isolators and labyrinth seals. (Note that virtually all sleeve bearings are oil lubricated, whereas most rolling element bearings are grease lubricated.)

Shaft surface speed and finish

Shaft surface speed is always a consideration for contact seals. If it’s excessive, overheating from friction will degrade the seal material and possibly damage the shaft surface. Table 2 provides limiting speeds for some common contact seal materials.

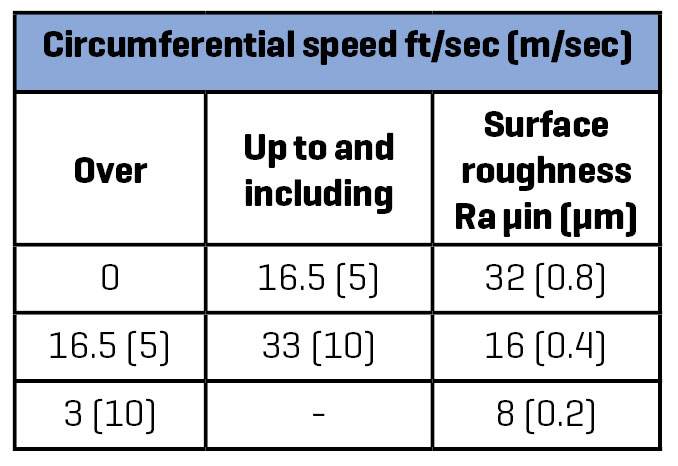

Contact seal friction and wear are also affected by shaft’s surface finish. Suggested shaftsurface finish tolerances are given in Table 3.

Images: EASA and SHUTTERSTOCK