Managing Machinery’s Silent Killer

Friction costs industry a lot of money and the biggest reducer of friction is effective lubrication. However, most companies today do not manage their lubrication process effectively and hence do not get the benefits of reduced friction in their machines.

Wear is one of the biggest fiction generators; simply put, when metal parts rub or touch, friction increases. Today wear in equipment is accepted, but not well understood. It is a killer of metal components, silent in its wearing process, until it reaches a detectable level and then it is too late as the damage has already been done. Effective lubrication management reduces wear and friction, and eliminates or reduces the Silent Killing process. This article is all about understanding how good or bad lubrication practices affect machine life and how to eliminate or manage the Silent Killer.

The fact that bearings and machinery suffer from wear is well known and accepted in industry. However, the mechanism that causes the wear, how to manage it or how to prevent it, is not so common.

Unless the operating lubricant is very clean and chemically sound, wear starts to occur the minute a component is put into service. The development of the wear is dependent on the hardness and size of the foreign particles, the load on the application and the effectiveness of the selected lubricant.

The types of wear we are referring to are abrasive wear and adhesive wear. Abrasive wear occurs when there are particles in the lubricant that are greater in size than the lubrication film thickness itself. Adhesive wear occurs if the lubricant does not provide sufficient separation of the mating surfaces causing metal to metal contact.

The silent killing phase is the period of time it takes for the wear process to reach the point where the damage can be detected by traditional means. Examples of damage detection include an increase in overall vibration levels, seal leakages and heat generation.

As we have discussed, the problem we face is that when we are able to detect this level of wear, the damage has already been done and cannot be reversed. All we can do at this stage is manage further deterioration of the worn part and prevent catastrophic failure.

What most people do not understand is that the lubrication film thickness is very small – only a few microns; as a result it doesn’t take large contaminants to start the wear process.

Managing the Killing Process

The bad news is that the wear responsible for the Silent Killing process starts from day one of operation of a new component or piece of equipment. The good news is that it can be prevented and the POINT OF NO RETURN can be significantly extended in time. It can almost be eliminated – meaning a significant increase in component life or MTTF (mean time to failure). This all naturally relates to an increase in equipment uptime, a reduction in maintenance needs and costs, and consequently to an overall increase in operating performance and results.

The difficult part in achieving an increase in operating performance is the prevention of the silent killing phase. This can be summed up with just one statement – one need to manage the lubrication processes more effectively. In other words implement a Lubrication Reliability strategy.

Lubrication Management

The term Lubrication Reliability describes a process that ensures the lubrication works in a reliable manner. If it does not, an effective separating lubrication film thickness is not achieved and the process of wear starts to occur.

There are many factors that can affect an effective lubrication process, and therefore prevent the creation of a good separating lube film thickness. These can be addressed by applying the 6 Lubrication Rights (6R’s) to each and every lubrication point. If any of the following questions are not answered positively, then we stand a good chance of the Silent Killing process kicking into gear.

The 6 Lubrication rights are:

• The Right Lube

• At the Right Time

• In the Right Quantity

• In the Right Place

• In the Right Way

• In the Right Condition

Reducing the Killing Process

Cleanliness control is the most critical component of an effective Lubrication Management Strategy, as contaminated oil is the biggest cause for machine and component wear. Without this, the Silent Killing process goes into effect. This is managed by effective filtration processes, driven by oil analysis. However, many organizations have not recognized the need to invest in having clean oil operating inside their machines or equipment.

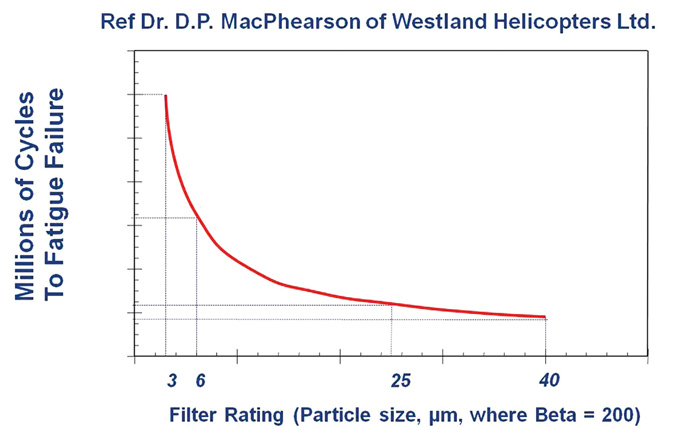

Research conducted by Dr. MacPhearson from Westland Helicopters showed the relationship between filter ratings and clean oil to millions of cycles, to fatigue failure of a bearing.

What this says is that the cleaner the oil the longer the bearing life. If you have a fine filter rating of 3µ, you can maximise bearing life. See figure 1.

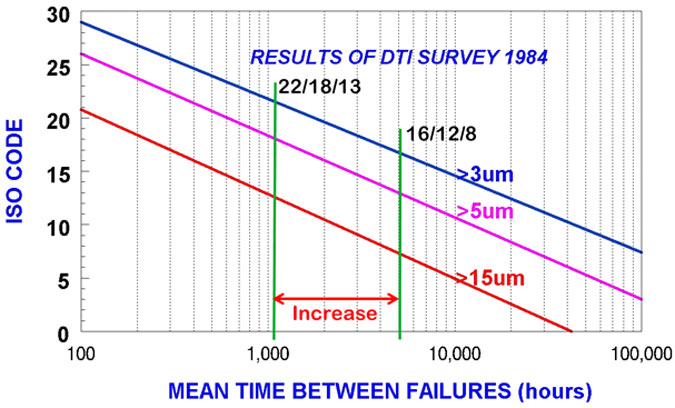

The most common measurement used to assess the contamination level in oil is compliance to ISO 4406 cleanliness standards. The achievement of a lower ISO 4406 cleanliness code, from 22/18/13 to 16/12/8, can be regarded as a best practice level for hydraulic systems. This will significantly increase component or machine life. Note on figure 2 the mean time between failure increases, due to the lower ISO 4406 codes.

Controlling the Process

Companies that understand the benefits to be gained from having an effective lubrication process in place are consistently managing the process. This generally entails dedicated and well-trained staff, consistent adherence to the 6 lubrication rights and the use of a dedicated lubrication database.

Many companies use their existing CMMS system to manage their Lubrication activities. Our experience is that most of these systems do not go into enough detail to effectively manage the activity. The best assessment on how effective your lube management system is would be to ask the following six lubrication right questions for the every lube point. If we can answer yes we have a best practice situation.

If not then rest assured the Silent Killing process will be in play.

From our years of experience at lubrication plant practices, we have determined the base standards that need to be in place in order to achieve best practice levels. These can be broken down to 4 key areas, covering; 1 - the strategic part, 2 - the cleanliness control and contamination part, 3 - the database management and reporting section, 4 - lubrication knowledge and its applications.

Also we endeavour to determine how advanced the complete lubrication strategy is on a maturity scale. We generally see that the implementation of a best practice standard goes through 4 evolutionary steps – basic requirement, lubrication processes, proactive lubrication management and the overall plant asset efficiency culture.

Base examples of each level are shown in the following graphic along with some important fundamentals for each component and maturity level.

The Lube Room

Without exception, all plants that are at best practice levels, manage the oils correctly in their lube room or lube storage area. The lube room is the base standard of ensuring that only clean and chemically sound lubes are added to the equipment.

A best practice storage area standard clearly identifies the different lubes, filters the oil to a clean standard and protects the oil from moisture, dust or dirt, whilst controlling temperature variations. The best practice standard is the Oil Safe Bulk storage system. See Figure 3.

Dispensing System

The easiest standard to put into place is the OilSafe dispensing system. With its 10 different colours and drum sizes that match differing dispensing needs, along with many different and fully sealed filling mechanisms to suit all fill points, OilSafe is undoubtedly the global best practice in lubrication dispensing.

The biggest sources of contamination for operating oil are airborne dust, dirt and water. Oil reservoirs need to breathe and if they do not have breathers that condition the air on the way in, then the oil easily gets contaminated. Desiccant breathers are an excellent tool for not only stopping dust and dirt particles from entering the oil, but they also absorb moisture from the air.

The best practice desiccant breather on the market today, in our opinion, is the Air Sentry Guardian breather. The breather not only filters for dust, dirt and absorbing moisture, it also has a unique check valve technology ensuring that any exhaust air does not go through the breather thereby further contaminating the water absorbing gel. It simply makes the breather last much longer – it is the best value for money on the market today.

A best practice tool for training the staff on this subject is the Reliability Institute’s Bearing Failure and Causes on line training programme. This course can be found on the Reliability Institute Web Site: www.reliabilityinstitute.com .

The company Enluse BV specializes in helping industry to achieve best practice standards in lubrication reliability, which is the process to eliminate the Silent Killing process of the bearings. We can be contacted via the following homepage: www.enluse.com